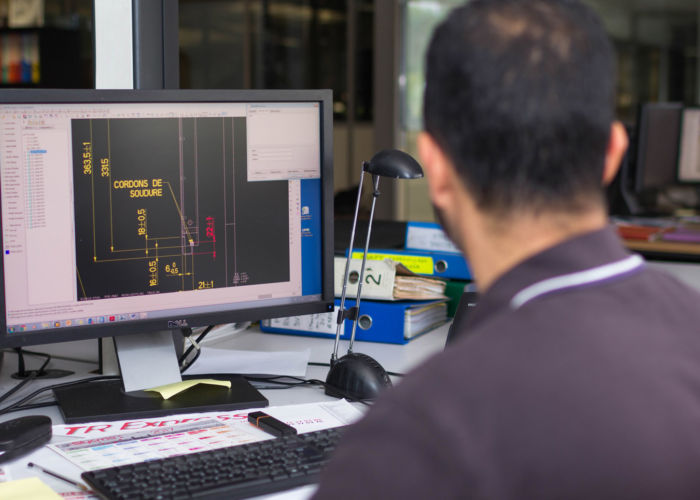

An in-house design office,

for your custom projects

Slycma has designed and made its own products for over 40 years. Its design office has a threefold mission: to develop new products, to adapt the standard products and to anticipate market demand.

We support you at every stage of your project

Each situation is unique. That’s why we offer support when you’ll most need it in order to take stock of your issues. Whether they are related to the dimensions, the aesthetics or the more technical aspects, we immediately recommend the solution that is best suited to your individual situation.

Once the feasibility has been confirmed, our standard product is then redesigned according to your personalised solution. The specific parts are manufactured in our workshops. The assembly instructions specific to the product and situation are drawn up.

Each of the major steps involved in the manufacturing process right up to the packaging stage are specifically monitored. Each finalised project is made within a period of 4-8 weeks, depending on the complexity of the door and/or the finish requested.

Each lift door is created right here

Every door made at Slycma, whether it’s a standard model or custom-made, is treated with the same passion and desire for improvement, innovation and quality.

For 40 years, our design office, equipped with leading design tools has developed its extensive knowledge base by acquiring valuable experience and know-how from each door that has been designed.

Its main aim has always been to create robust, reliable and silent doors that are made to last.

7 specialists who relish the challenge that each door presents

The issues surrounding the modernisation of lifts have been a key aspect of our corporate culture for over 20 years. We see them as challenges to overcome.

In order to do this, each member of the team must apply all their skills and knowledge acquired to each individual project. They will know THE solution that best meets your specifications.

And the same goes when creating new ranges of doors that will fit seamlessly into future buildings equipped with state of the art technology. As they constantly keep themselves updated on the trends and patterns occurring within the industry, they are able to anticipate and design solutions for current and future markets.

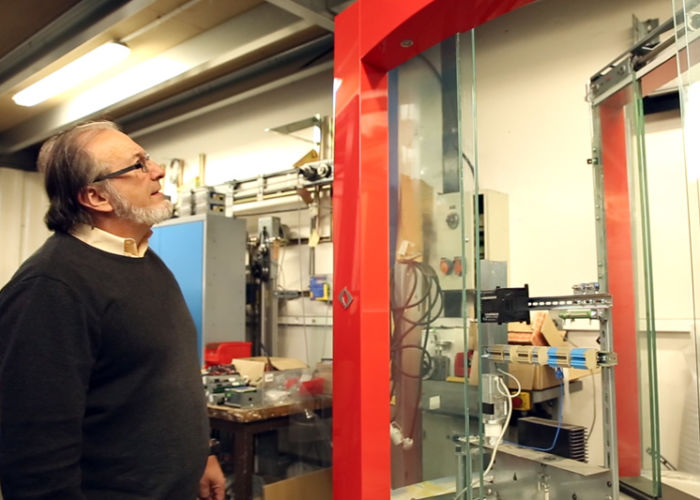

A test laboratory where each door is given a thorough inspection

We have been using this tool ever since the company was founded over 40 years ago.

ISO 9001 and MODULE H certified (Annexe VII de la Directive 2014/33/UE), we are competent and authorised to carry out all relevant stress and endurance tests on our products, standard or custom, which is a mandatory step before they are made available on the market.

Whether it’s a Charpy impact test, measuring the deformation when pressure is applied to the door panels, noise emission measurement tests or even endurance tests carried out on several million manoeuvres and normative tests on the locking systems.

These tests allow us to market products with the peace of mind that they are compliant to standards and safe for those who will rely on and use them.