Here you'll find practical guides for installing your elevator doors and tips for taking accurate measurements. Simple and clear, they support you at every stage for efficient and stress-free work.

See an impact test

Each project is unique. That’s why we support you wherever needed, taking into account your specific constraints. Whether dimensional, aesthetic, or technical, we recommend the solution best suited to your needs right away.

Once feasibility is confirmed, our standard product is redesigned to meet your specifications. Custom parts are manufactured in our workshops. Project-specific installation instructions are prepared.

Each major step — from manufacturing to packaging — is closely monitored. Once validated, your custom project is produced within 5 to 8 weeks, even for the most complex or highly customized doors.

Every door manufactured at Slycma, whether standard or custom-made, reflects our dedication to continuous improvement, innovation, and quality craftsmanship.

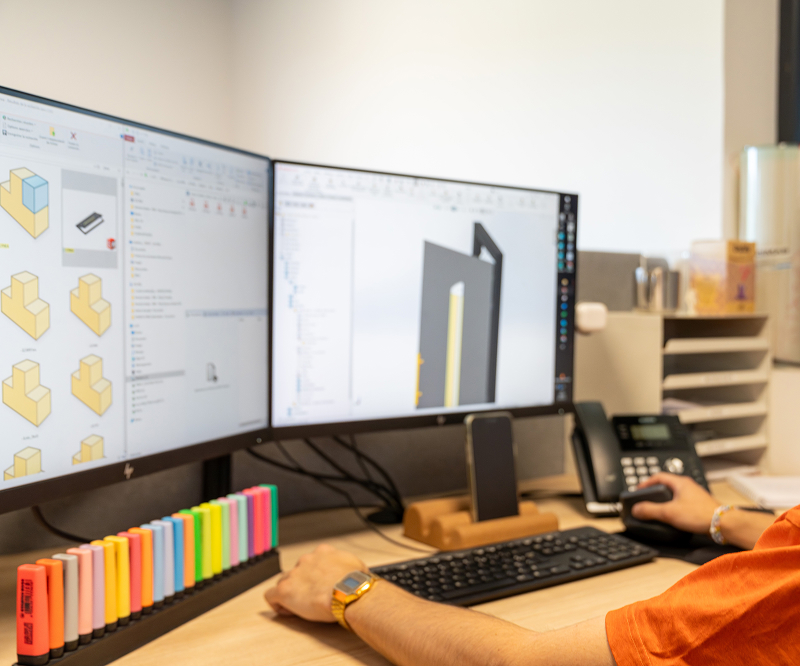

For over 50 years, our design office, equipped with industry-standard design tools, has built its expertise by capitalizing on every door developed.

Its core mission has always been to design doors that are robust, reliable, quiet, and built to last.

Elevator modernization has been part of our company culture for over 30 years. Each project is a challenge to be met.

Each team member brings all their skills and knowledge to every case. They know how to design THE solution that best meets your specifications.

The same applies to the development of new door ranges, perfectly suited for the buildings of the future and equipped with the latest technologies. Thanks to their continuous monitoring efforts, they are able to anticipate and design solutions for both current and future markets.

We’ve had this testing tool since the company’s inception over 50 years ago.

Certified ISO 9001 and MODULE H (Annex VII of Directive 2014/33/EU), we are fully qualified and authorized to conduct all required resistance and endurance tests on our products before they go to market — whether standard or custom-made.

These include pendulum impact tests (rigid and soft), deformation under pressure, noise emission measurements, endurance tests over millions of cycles, and of course, regulatory locking system tests.

All of these allow us to confidently market components that ensure the safety of both passengers and technicians.